Top Tech P20G-2-R Automatic Grinding Polishing Machine – Dual Platten

Overview

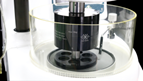

The P20G-2-R6 grinder polishers is the dual platten version of the P20G series of automatic grinder and polisher. It has been designed for ergonomic application for grinding and polishing application. It is suitable for laboratory with demand for high through put and high productivity. It has been designed with a streamline appearance and a glossy film surface finishing making the appearance artistic and exquisite.

Benefits & features

Exquisite Appearance

Streamline appearance design and glossy film surface finishing makes the mechanical appearance artistic and exquisite.

Multi-functional control panel

It is equipped with a high-quality color touch panel, intuitive human-machine interface, and 10 modules of parameter memory function.

Low speed grinding and polishing function

Rotational speed can be lowered to 1 rpm. With external dispenser (optional), it meets the requirement of long-time polishing process without deformation.

Rotational speed of the head is adjustable

The grinding head is equipped with brushless motor with rotation speed from 10~170rpm.

Dispenser (Optional)

Users can control the dispenser by setting up the parameters on control panel.

Automatic drying function

The automatic drying function makes the cleaning process more fast. Also, avoiding the cross contamination during the operating process.

Sample Pistons

Sample pistons will lower down lightly to prevent the surface of the specimen from damage.

Overload protection

When the total force is more than the default setting during operation, the machine will stop automatically.

Modular design

The combined control box can be fixed behind the machine or be placed next to the machine with quick-change design, which is easy to maintenance and can maximize the space.

Individual pressure

Pressing force is between 0.5~6kg. The suggested pressure and amount of samples are marked on the grinding head.

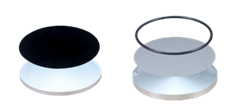

Various choices of platen

Platens with size 8” and 10“ are suitable for any kinds of consumables.

Individual micro force (Optional)

Pressing force is between 0.2~1kg. Suitable for the specimen, requiring the micro force pressing during grinding/polishing.

Central force (Optional)

Pressing force is between 3~12 kg. Quick-released sample holder simplifies the leveling process and cleaning process.

Telescopic water hose and air pressure gun

The machine can be cleaned conveniently.

Various Anti-splash application

Various anti-splash covers can be applied based on the method of polishing process.

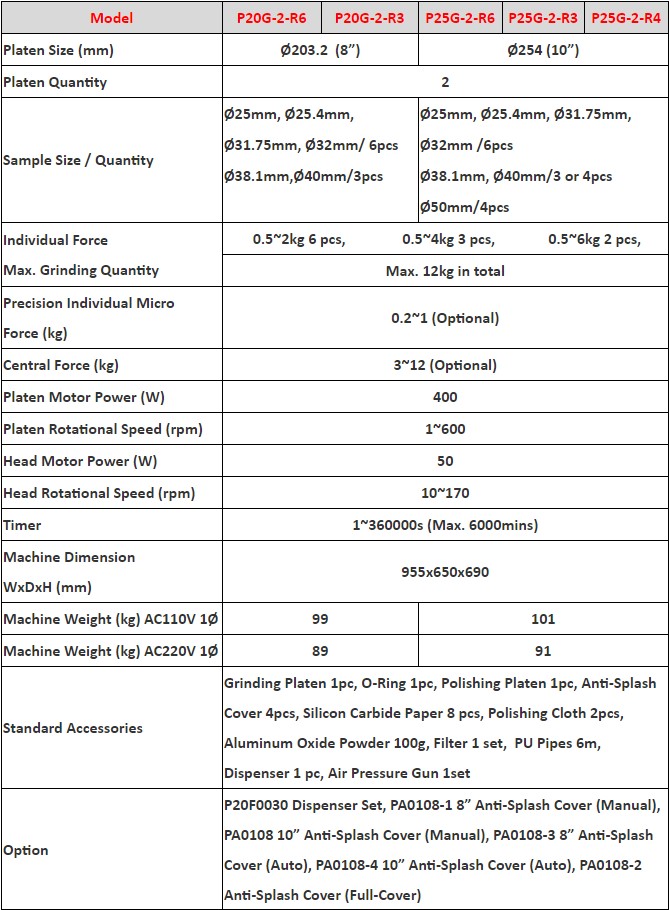

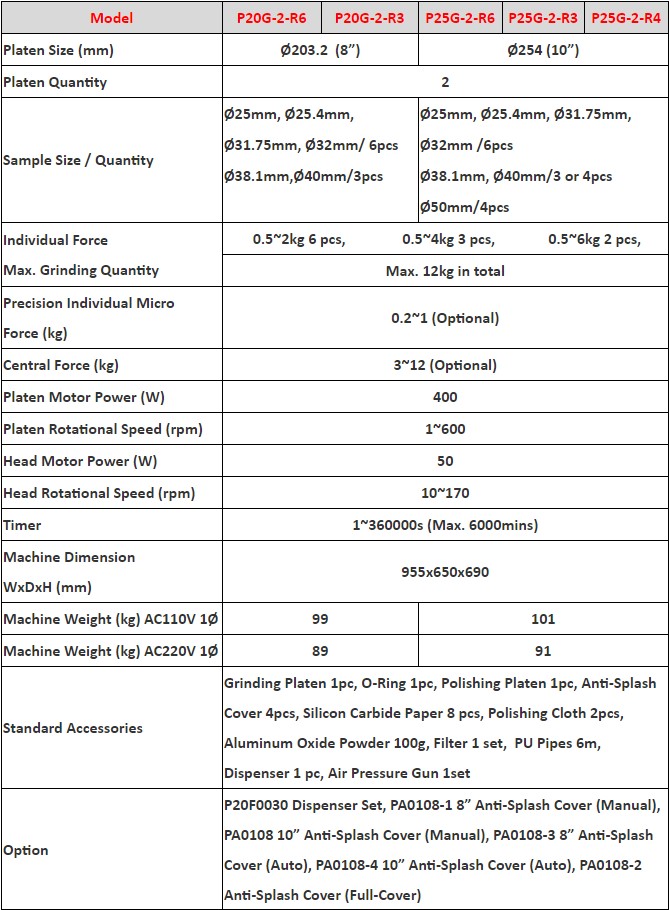

Specifications