Solarius Phoenix Surface Profilometer

Overview

Phoenix is Desktop 3D Optical profilometer for lab quality control. Depending on specific needs, different types of 3D sensors can be configured, making it a flexible tool that quickly scans profiles in 150mm x 150mm available range and extract required features to be measured. Data analysis software allows automation and efficiency in a production environment.

Key Features:

Non-Contact 3D Surface metrology

Quick, easy to make measurements with automated reporting

Customized recipes, easy to automate

Defect detection and analysis

ISO and ASME compliant results

Precise 3D Inspection

The new Phoenix Desktop 3D surface measuring system from Solarius enables highly accuracy and precise 3D surface inspection. Thanks to high precision data acquisition, data processing allows a complete 3D reconstruction of the profile and extract required feature to be measured.

Reliable technology

Phoenix 3D Optical Desktop system is based on Chromatic Confocal technology. This allows nanometric axial resolution without moving the part and without ambient light interference. In addition, Phoenix features a precise

automated X/Y positioning unit with 150mm x 150mm travel range and a manual height measuring range of 100mm. Each component contributes to provide accurate, precise and repeatable measurement results.

Easy and Powerful Software

In order to provide flexible but powerful inspection capability, Phoenix takes advantage of easy to program Data acquisition and complete data processing SW. The intuitive and easy to operate software is a key feature

of all the Solarius products: new operators spend less time understanding the system and can perform more measurements in shorter time. After set up, measurement and data analysis procedures can be stored and executed

repeatedly at any time without additional efforts. Due to it’s sturdy mechanical design and high precision, Phoenix can be installed in the production line to monitor the quality of any manufactured product.

Typical Applications

• Surface Cosmetic inspection

• Volume

• Area

• Geometry

• Defect detection/inspection

• Coplanarity

• Wear & Tear

• Roughness

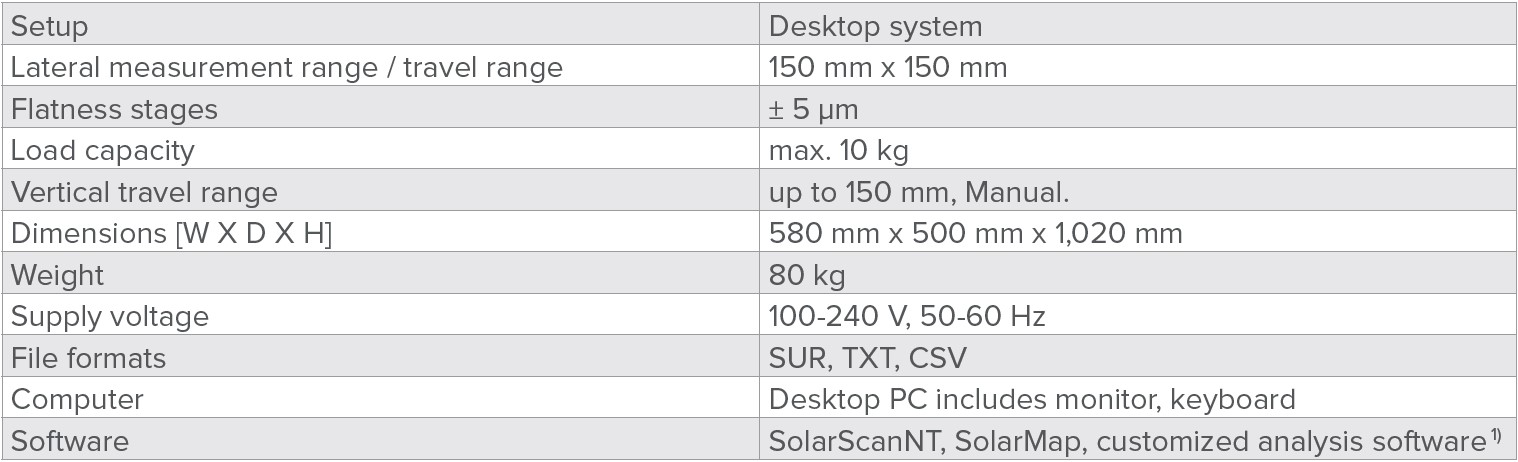

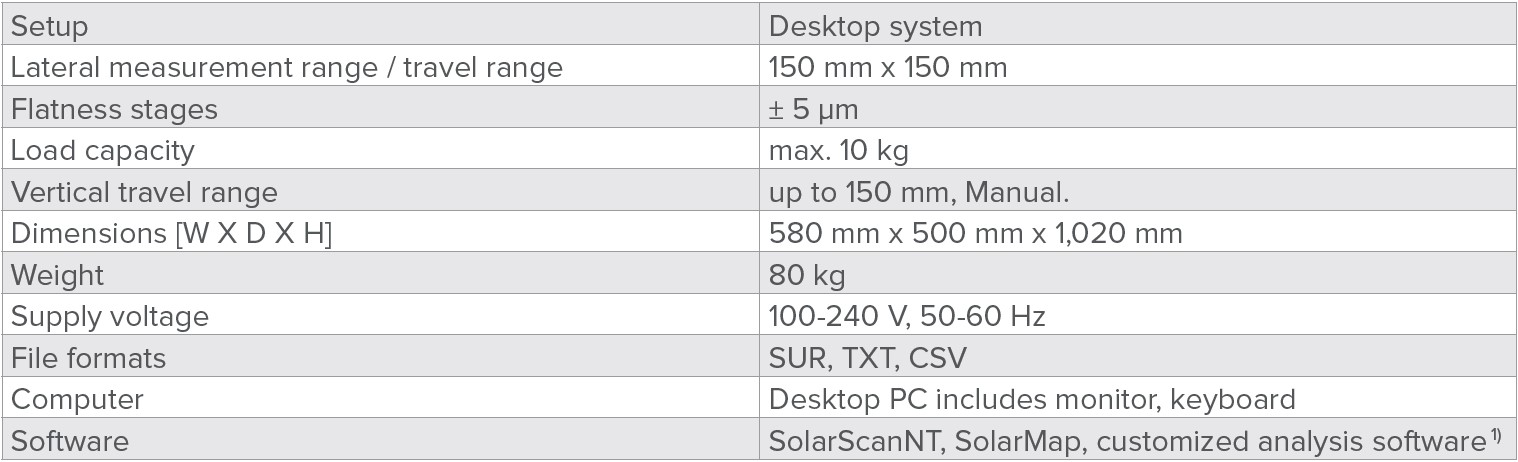

Contour and Area Measurement

Flatness and Straightness Measurement

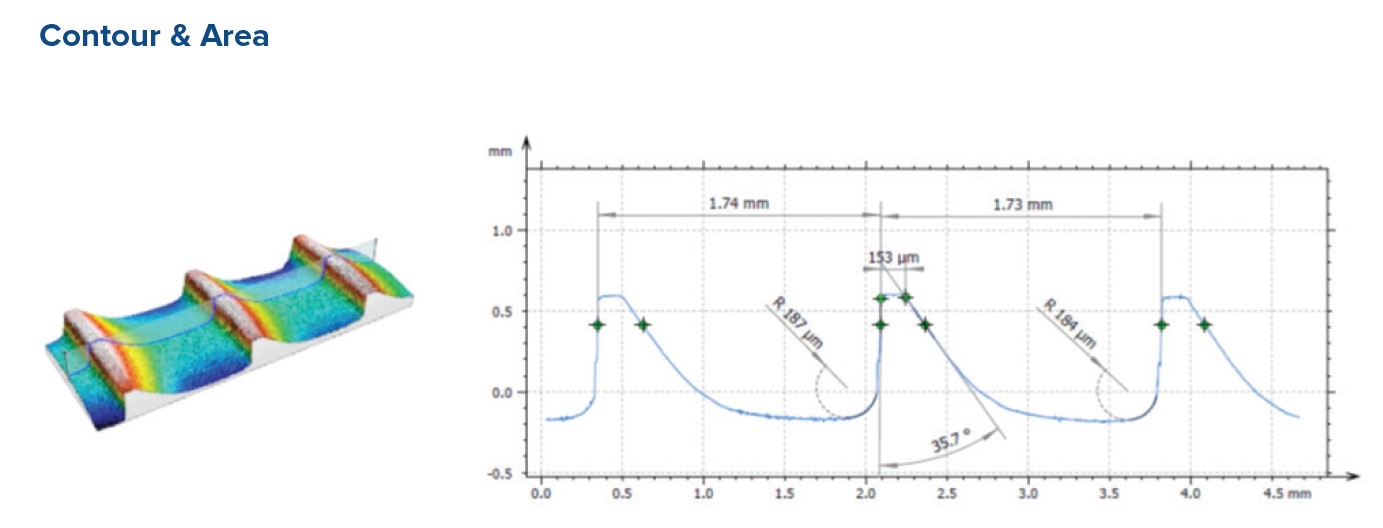

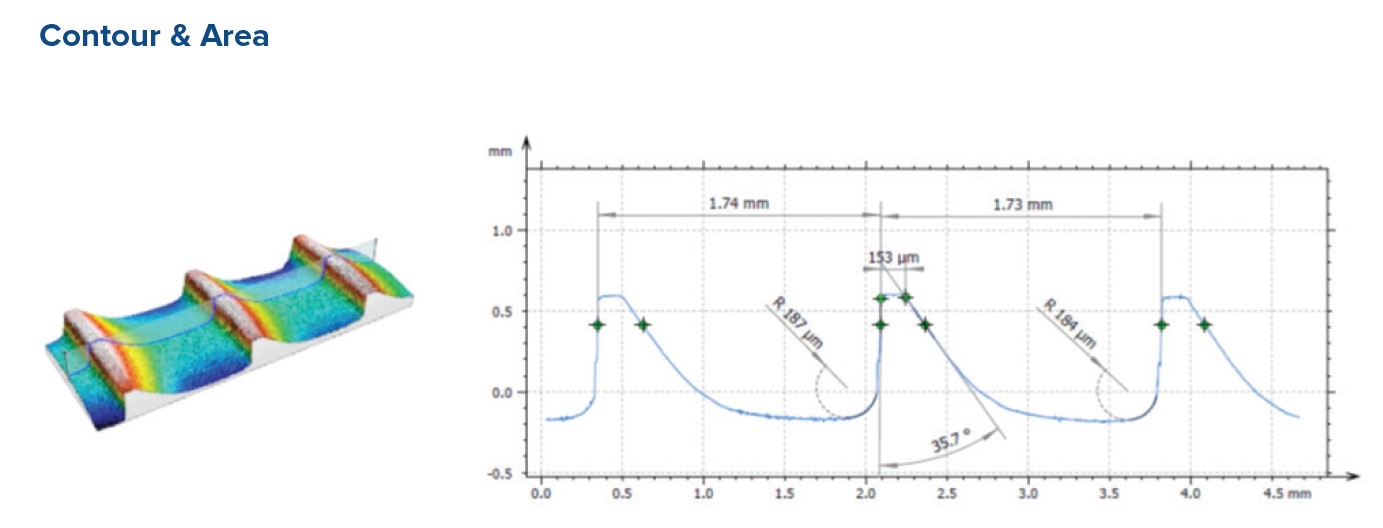

Volume Measurement

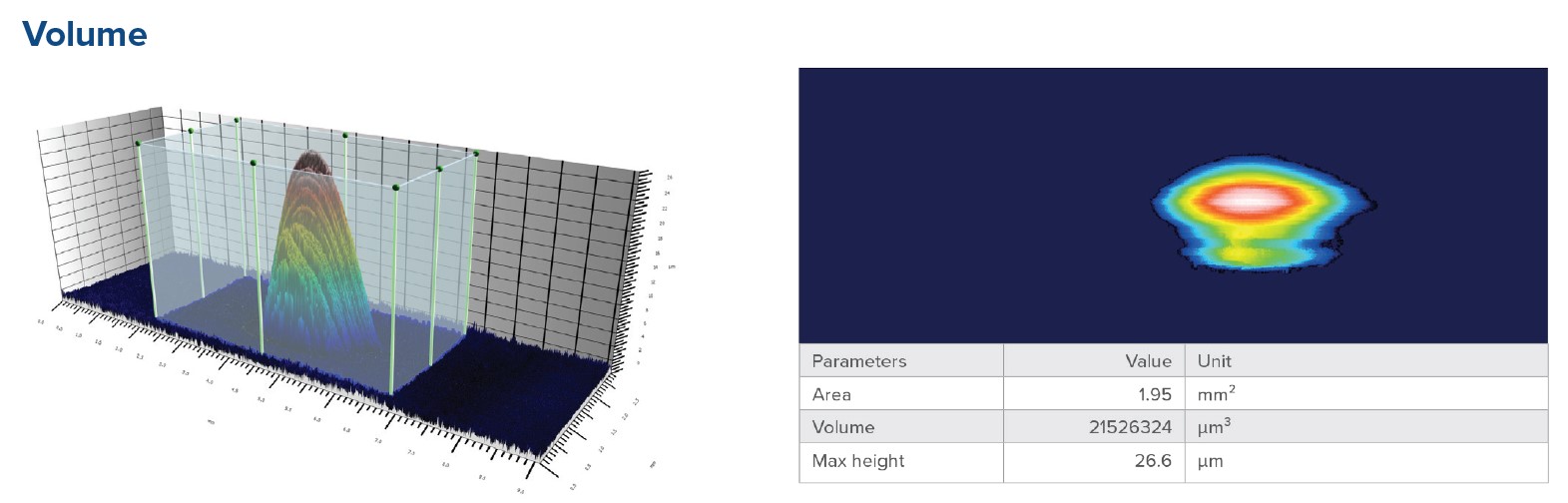

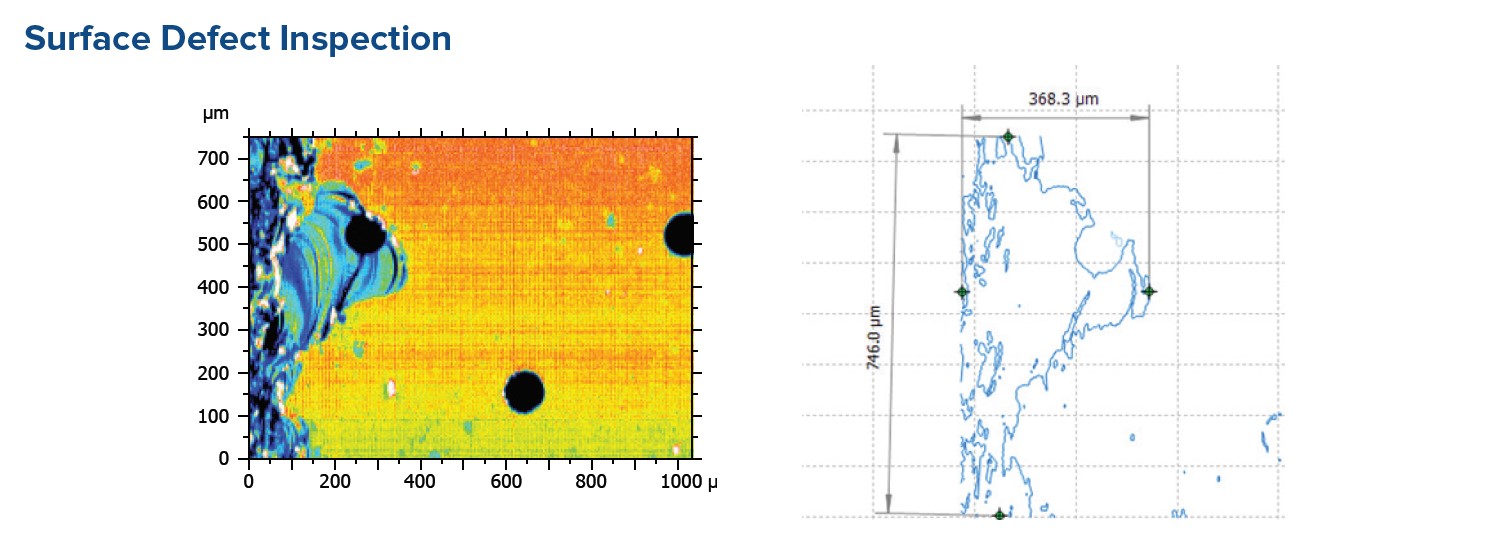

Surface Defects Inspection Measurement

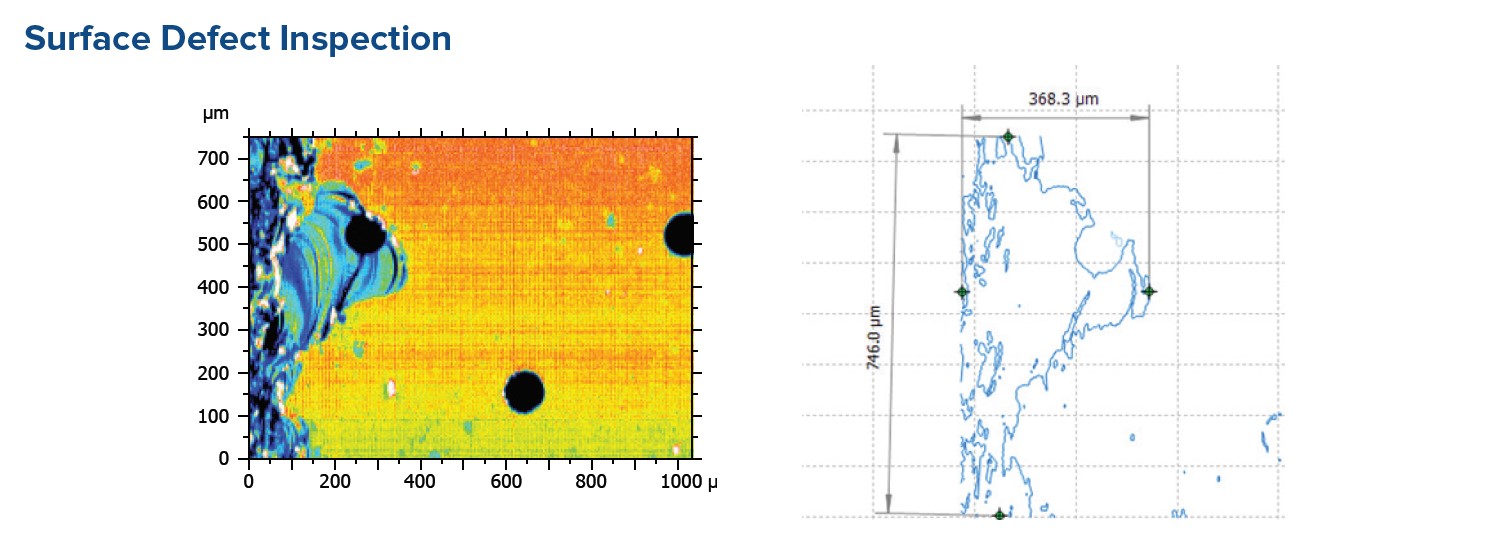

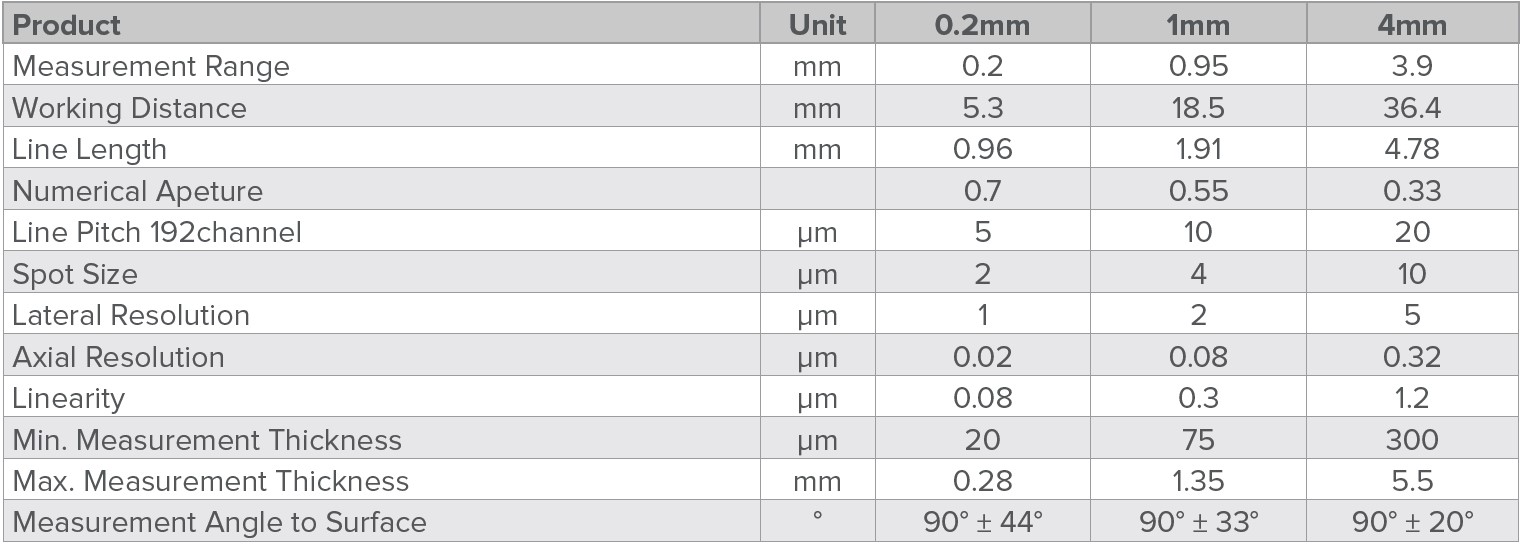

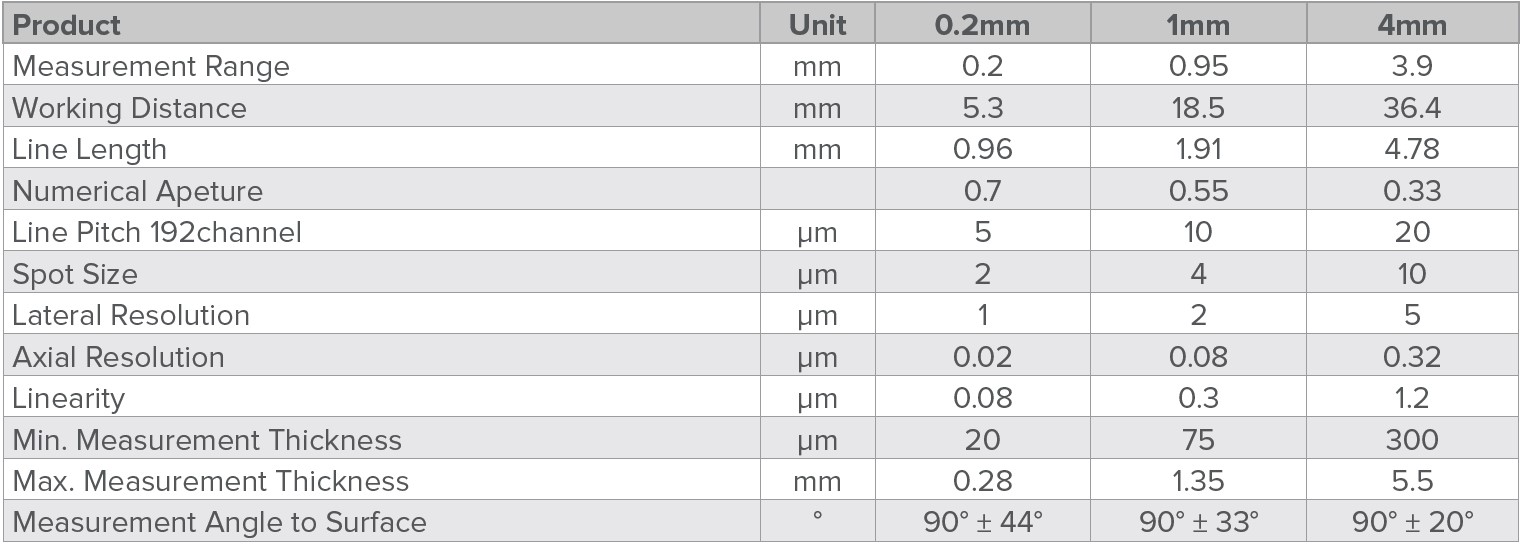

Technical Specifications

System Configurations